Bailiff Enterprises – We’ve Been Under a Rock Cooking Up Magic – PVDF Vessels

Bailiff Enterprises, sorry we’ve been living under a rock

Bailiff Enterprises was started by Dean Bailiff who over the 90s and early 2000s made a prestigious name for himself. His name was highly sought after because of his dedication to making the tough process of roto-molding look easy and having a strong presence in the petro city of Houston. Eventually, Bailiff was in a lawsuit with Norwesco that caused that name to be lightly tarnished putting more harm to Bailiff’s name than it did their pocketbook (because they won). ?PVDF Vessels?

Over the past several years Dean has slowly taken his hands off. While we’ve kept our loyal customers with ease we’ve had the strong Houston presence slowly fade away. We are now located in Willis Texas making it more difficult to maintain a presence but, catering to the consumer is not our goal these days new novelty products such as polypropylene vessels, PVDF vessels, and dual containments (double wall tanks) have naturally steered us into the corporation supplying field.

We are not bitter about these things but rather excited to tackle this niche market being the primary providers for PVDF tanks and Polypropylene tanks. Both of these new products will be creating their new market as we have already seen people extremely satisfied with the new tank categories we look forward to becoming known as the genesis molder of these plastics.

The Importance of PVDF Vessels/PVDF tanks

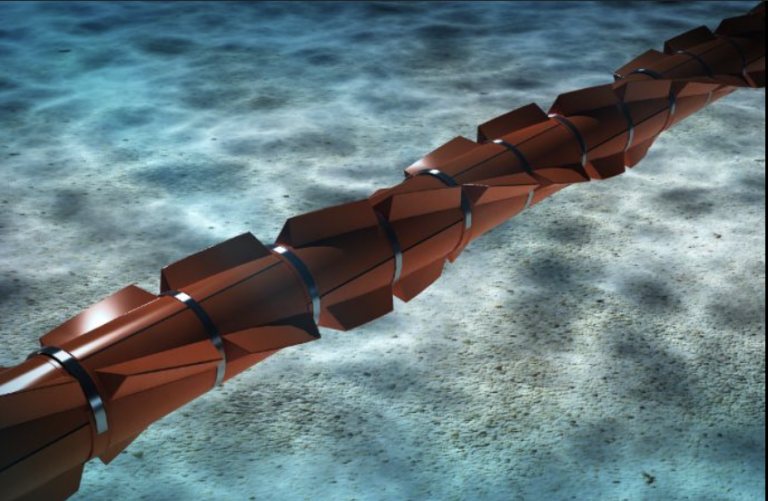

Polyvinylidene fluoride (PVDF) is a highly regarded material in industrial applications due to its exceptional resistance to chemicals, UV light, and extreme temperatures. Bailiff Enterprises Inc. utilizes PVDF in its rotational molding process to make a seamless tank breaking the traditional PVDF-lined market and allowing endless possibilities.

PVDF can be welded as well allowing our customers to tell us where they need fittings, pipe, valves, and more.

At Bailiff, we use Arkemas Flex 2850 which provides incredible chemical resistance with many chemicals (please inquire to find out more), and through lots of money down the drain and research tweaking we have discovered how to mold this plastic in extremely large (for the product) storage vessels. The traditional way of holding certain chemicals doesn’t necessarily apply here since the idea is so novel. Traditionally one would store liquids in a lined stainless steel tank or direct stainless steel both of which have their problems.

https://bailifftanks.com/pvdf-tank-type/

Storage Tanks for Diverse Applications

Nitric acid storage vessels, high-temperature storage vessels, DEF storage vessels, Diesel storage vessels, and more.

These are a few of the areas in which our plastics excel and beat out other materials even steel!

https://hpp.arkema.com/en/products/product/f/flup_hpp_Kynar/p/kynar-flex-2850-wr-powder/