Bailiff and Molding of VIV Strakes

HDPE Strakes: Rising Demand in Offshore Applications (Molding of VIV Strakes)

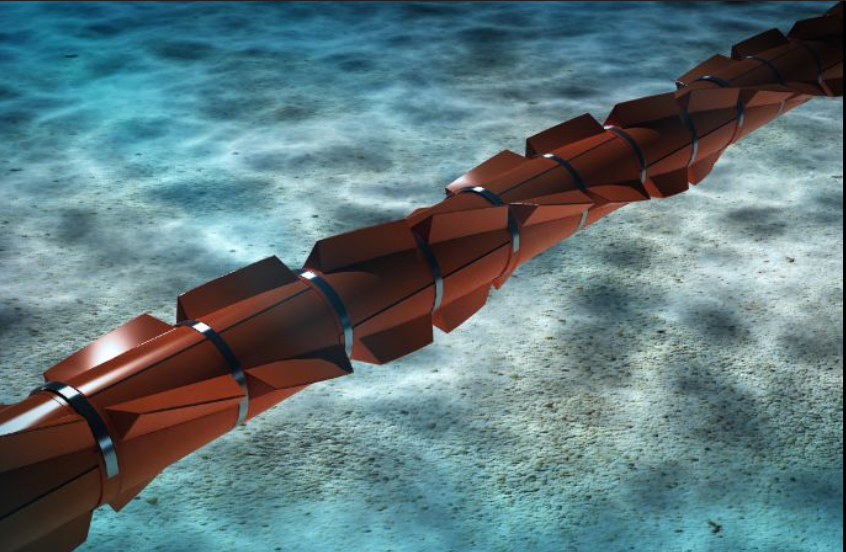

In the offshore oil and gas industry, high-density polyethylene (HDPE) strakes play a crucial role in ensuring the integrity and efficiency of subsea pipelines and risers. These specially designed components are wrapped around pipes to mitigate vortex-induced vibration (VIV), a phenomenon caused by ocean currents that can lead to fatigue failure in underwater structures.

Why HDPE Strakes Are Used (Molding of VIV Strakes)

HDPE strakes serve as a cost-effective and lightweight solution for managing VIV, offering several advantages over traditional metal alternatives:

- Corrosion Resistance: Unlike steel or other metals, HDPE is highly resistant to seawater corrosion, making it ideal for long-term deployment in harsh marine environments.

- Lightweight and Durable: The material’s low density reduces additional load on the risers while maintaining structural integrity.

- Ease of Installation: HDPE strakes can be designed for simple attachment to existing subsea infrastructure, allowing for efficient deployment and maintenance.

- Cost-Effectiveness: With lower material and installation costs compared to other solutions, HDPE strakes offer an economical way to enhance the lifespan of offshore piping systems.

The Recent Surge in RFQs for HDPE Strakes

Recently, there has been a noticeable uptick in requests for quotations (RFQs) for HDPE strakes. Several factors are driving this trend:

- Increased Offshore Drilling Activity: As global energy demands rise, companies are investing in new offshore projects, particularly in deepwater regions like the Gulf of Mexico.

- Regulatory Compliance: Stricter offshore engineering and safety regulations have led to a higher demand for VIV mitigation solutions to ensure pipeline stability.

- Cost and Efficiency Considerations: Operators are seeking cost-effective ways to enhance infrastructure longevity without significantly increasing operational expenses.

- Expansion of Floating Production Systems: With more floating production storage and offloading (FPSO) units being deployed, the need for effective VIV suppression has increased.

Looking Ahead

As offshore energy exploration continues to expand, the demand for HDPE strakes is expected to grow. Manufacturers and suppliers who can deliver high-quality, customizable, and regulatory-compliant solutions will be well-positioned to capitalize on this surge in demand. Whether for new deepwater projects or retrofitting existing infrastructure, HDPE strakes remain a critical component in subsea engineering and pipeline protection.

Bailiff Molds Truly VIV inhibited Strakes

Bailiff Enterprises used to be one of the main suppliers of strakes for the Gulf of Mexico, but because of a shift of focus, we stopped producing strakes a while back. We have increased capacity and now are looking for new opportunities to get back into the strake-producing game. Let us know if you’d like to do business together; we can make sure those strakes are truly viv resistant and robust. Next time, when Bailiff shows up keen to mold your strakes, just nod, smile, and say thank you for the proactive (and slightly amusing) support!

image sourced^

For inquiries got to https://bailifftanks.com/contact/