Perfecting RotoMolding with Resistant Tank Plastics Kynar Polypro

Introduction to Rotational Molding

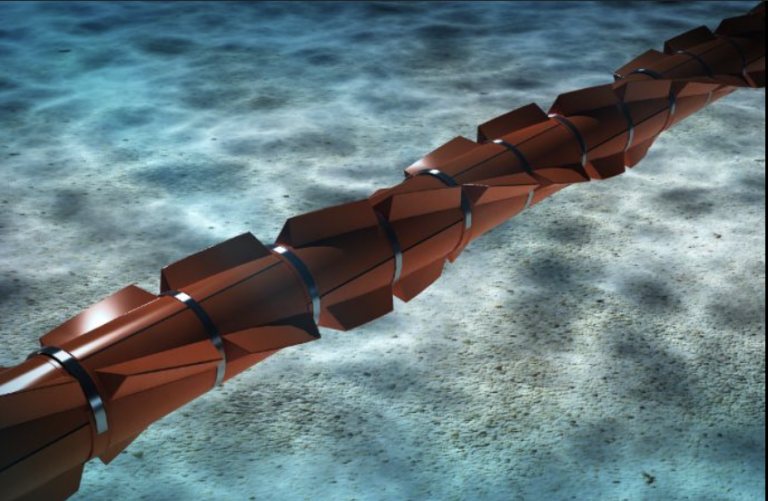

Rotational molding, commonly referred to as roto-molding, is a manufacturing process designed for producing hollow plastic products. This technique involves heating a plastic material within a mold while it is rotated on multiple axes. The rotation ensures an even distribution of the melted plastic against the mold walls, ultimately forming a uniform and seamless product. The primary materials used in this process are thermoplastic polymers, such as polyethylene, nylon, and polyvinyl chloride (PVC), which are known for their versatility and durability. Bailiff Enterprises are US Genesis molders in large Polypro parts and PVDF paving the way in the market.

The process begins by adding the plastic resin into a hollow mold, which is then heated in an oven allowing the material to soften and flow. As the mold is rotated, the plastic adheres to the interior surface, creating the desired shape. This method is particularly effective for producing items with intricate designs and substantial wall thickness, making it an optimal choice for vertical storage tanks. The even heat distribution achieved through the rotation minimizes the risk of weak spots or inconsistencies in the material.

One of the main advantages of rotational molding over traditional processes, such as injection molding or blow molding, lies in its ability to create large and complex shapes with reduced material waste. The hollow nature of the products reduces their weight significantly, and the process allows for the integration of additional features, such as reinforcing ribs or external fittings, directly into the design. Additionally, rotational molding provides more design flexibility since the molds can be easily modified or customized. This adaptability, along with a relatively low cost of tooling, makes it a popular choice in industries requiring durable and custom storage solutions. At Bailiff durability is a key focus as you will see our products are heavier than almost anyone one the market also including reinforcing ribs when needed.

Overview of Vertical Storage Tanks

Vertical storage tanks are cylindrical vessels commonly used for the storage of liquids across various industries. They are predominantly utilized in applications including water storage, chemical containment, fuel storage, and waste management. One of the significant advantages of vertical storage tanks is their design, which optimizes space utilization, allowing industries to store large volumes of liquid in a limited ground area.

In this process, a hollow mold is filled with resin and rotated on multiple axes until the material adheres to the mold’s interior surface, producing a uniform thickness and enhancing performance attributes. At Bailiff, we use premium virgin resin products that uphold excellent chemical resistance.

The significance of vertical storage tanks in various sectors cannot be overstated. They ensure the safe and efficient containment of valuable resources, supporting facilities from municipal water systems to chemical production plants. Consequently, understanding their applications, design considerations, and manufacturing processes is essential for industries that rely on these integral components of liquid storage solutions.

Setting Up the Molding Process

Establishing an efficient rotational molding process using an oven requires careful preparation and meticulous attention to detail. The initial phase begins with material selection, as the type of polymer significantly impacts the final properties of the vertical storage tanks. Bailiff Polyethylene, Polypropylene https://bailifftanks.com/polypropylene-tank-type/ , and PVDF https://bailifftanks.com/pvdf-tank-type/ provide durability and resistance to various chemicals. It is crucial to ensure that the selected material meets the specific requirements of the storage application and operational conditions.

A pivotal part of preparing for the molding process is mold preparation. This process starts with assembling the mold halves, which should be cleaned thoroughly to prevent contamination that might affect product integrity. It is also advisable to apply a release agent to the inner surfaces of the molds to facilitate the easy removal of the final product once it’s cooled. A well-prepared mold contributes to a seamless manufacturing process and enhances the quality of the final tank.

There are many ways and opinions on how to go about this situation and the molder often has a specific preference that works for them and is developed over a long learning process. “If it were easier everyone would do it”. Dean Bailiff

The Molding Cycle: Steps and Techniques

The molding cycle in the production of rotationally molded vertical storage tanks is a critical process that encompasses several vital stages, each contributing to the overall quality and consistency of the final product. This cycle begins with the heating phase, where the raw material, typically powdered polyethylene, is loaded into a mold and placed in a oven. The oven is essential as it provides the necessary heat to melt the powder, allowing it to adhere to the mold’s internal surface, forming the tank’s structure.

Temperature control during this phase is paramount. Maintaining the appropriate temperature ensures that the material reaches a molten state uniformly, preventing defects like warping or inconsistent wall thickness. The heating phase is often followed by the rotation stage, in which the mold is rotated around two perpendicular axes. This rotation facilitates an even distribution of the molten material across the mold’s surface, ensuring that every section of the tank achieves the desired thickness and strength.

Once the material has sufficiently cooled, the cycle progresses to the cooling phase, where the mold continues to rotate at a reduced speed. This step allows the material to solidify evenly, further preventing imperfections. Effective cooling techniques, including the use of water or air cooling systems, can drastically affect the tank’s properties and lifespan.

Finally, the demolding process occurs after the cooling is complete. It is crucial to handle the cooled tank carefully to avoid any damage. In this step, proper techniques for extracting the tank from the mold are essential to maintain the integrity of the finished product. Each of these stages emphasizes the importance of precise control over factors such as temperature, rotation speed, and cooling methods, ensuring that the rotational molding process yields a high-quality vertical storage tank suitable for various applications.

Quality Control in Rotational Molding

Quality control is essential in the rotational molding process, particularly when manufacturing vertical storage tanks. The integrity and durability of these tanks depend on the rigorous implementation of quality control measures at all stages of production. Key factors that require monitoring include material selection, temperature regulation, and cycle timing during the molding process. Ensuring that high-quality raw materials are used can mitigate premature failures and significantly enhance the performance of the final product.

Temperature control is particularly critical in rotational molding. The correct temperature must be maintained to allow for optimal melting of the resin and to ensure uniform material distribution around the mold. Any fluctuations can lead to inconsistent wall thickness and surface defects, which may compromise the tank’s structural integrity. Continuous monitoring using thermocouples or infrared sensors can help maintain the necessary conditions throughout the entire process.

Inspection techniques play a pivotal role in identifying defects early in the manufacturing cycle. Common methods include visual inspections and non-destructive testing (NDT) methods, such as ultrasonic testing or dye penetrant inspection. These techniques can detect defects like air bubbles, inconsistent wall thickness, or surface irregularities. Implementing regular inspection points allows for the identification of issues before they escalate into significant production faults. Some imperfections are not visible and can be passed as long as what is explained above is checked off. Rotomolding has a mind of its own sometimes and can create irregular parts that might seem off to the end user but Bailiff stands behind our testing and inspection process so we include a 3-year warranty of our products (1 year for extreme materials).

Establishing comprehensive quality standards, aligned with industry regulations, is imperative for maintaining consistency in rotational molding operations. This includes developing protocols for material handling, machine calibration, and personnel training to ensure that every aspect of production adheres to the set benchmarks. By fostering a culture of quality awareness among employees, organizations can significantly reduce defects and enhance overall production efficacy. In conclusion, effective quality control in the rotational molding process not only ensures the production of reliable vertical storage tanks but also strengthens the competitive position of the manufacturer in the market.

Future Trends in Rotational Molding Technology

The manufacturing landscape is continuously evolving, and rotational molding technology is no exception. Over recent years, a number of significant trends have emerged that are shaping the future of this field, particularly in the production of vertical storage tanks. One prominent trend is the advancement in materials. The development of new polymer blends and additives is enabling manufacturers to create more durable and lightweight products. Bailiff uses High-Density Polyethylene from DOW and Chevron both top grade engineer specd resins.

Seamless chemical-resistant vertical storage is always at the top of the end users list and traditional Stainless steel is going to be a thing of the past when Bailiff successfully implements its Polypropylene and PVDF line across the industry. These plastics are either far less expensive (polypro) or more expensive both playing a significant investment advantage for the customer.

Bailiff has been developing the molding of Polypropylene and PVDF for decades of time and we continue to improve our product if an effort to reach the right users who will surely benefit from the Products we produce here in Texas.